' Metal shaped any way you want! '

Metal parts and power coating

Molds and engineering

During the shaping and engineering phase, we conduct innovation studies, determining how to produce the parts. For the most precise approach we look at the geometry of the parts and the latest production methods. We then make the parts with tandem or progressive tools or as end systems. We handle everything related to your molds from design to finished product.

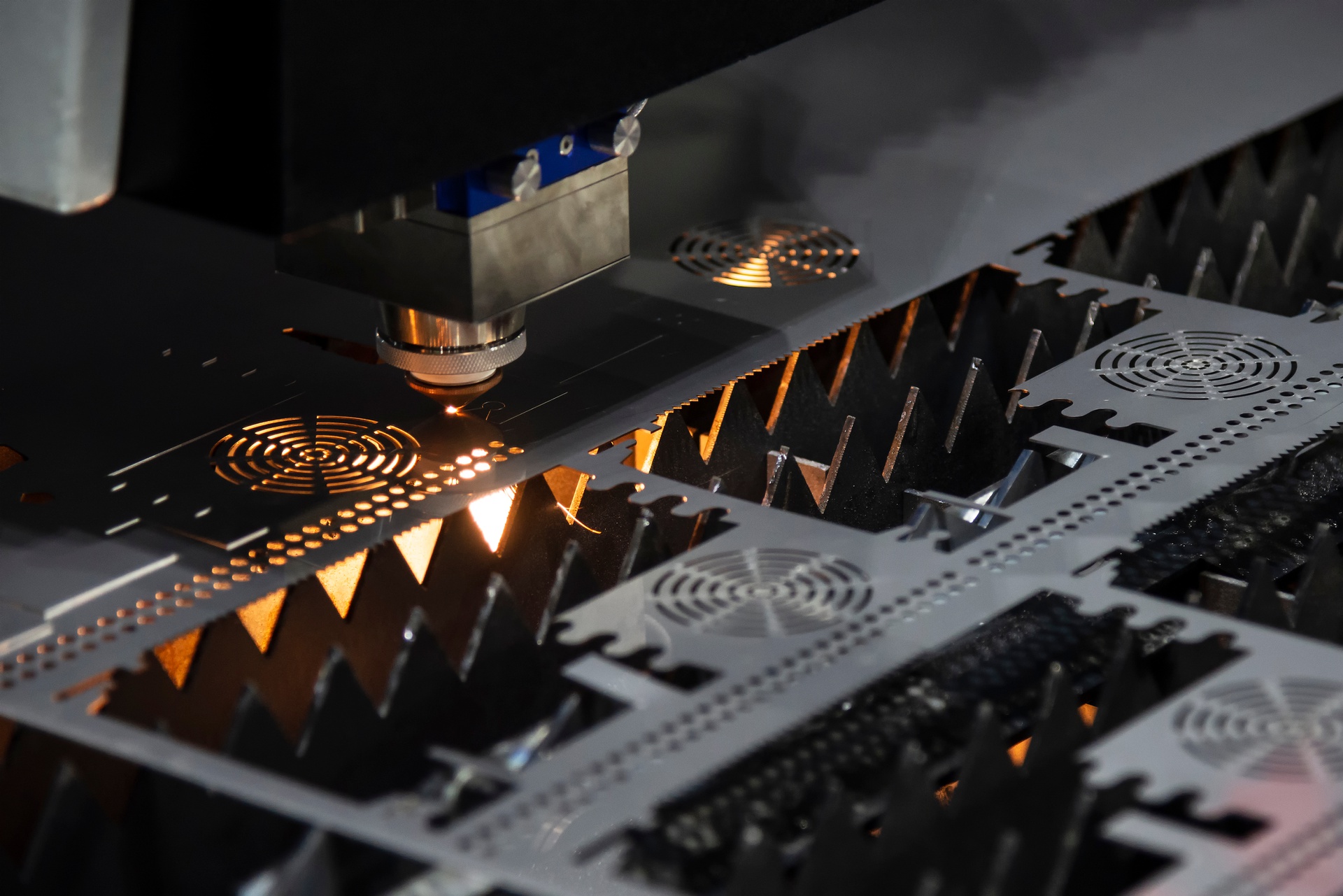

Laser cutting

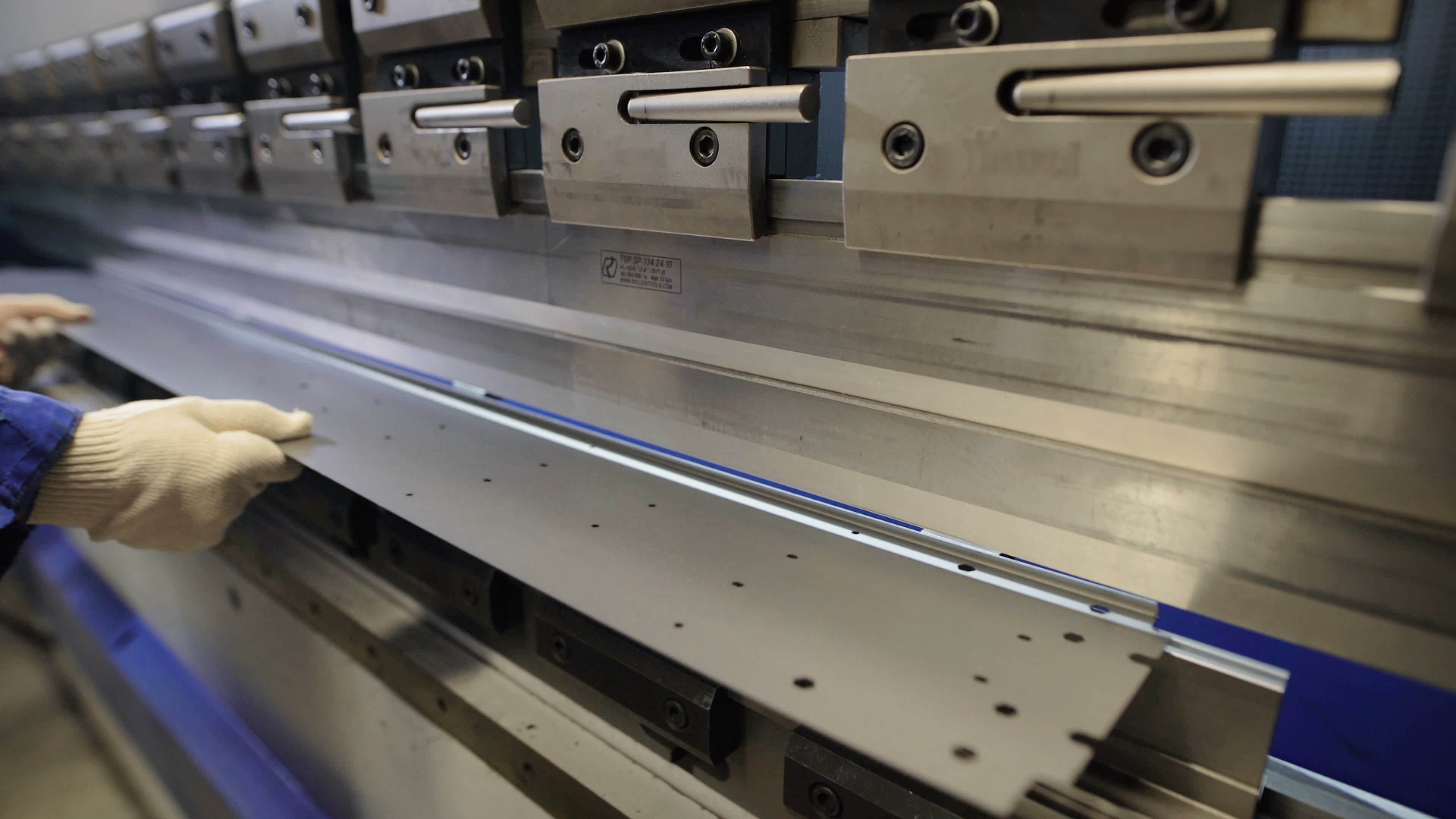

Our type C (25 to 175 tons) and type H (200 tons) eccentric presses as well as our hydraulic presses (250 tons) shape your metal parts. After forming, we can perform various surface treatments: deburring, vibratory deburring, polishing, and galvanizing. We can also set up special manufacturing lines depending on the size and shape of the parts.

Power coating

Our new fully automated powder-coating line lets us perform special surface treatments on parts up to 2.5 meters long and up to 1.5 high. Pre-treatment includes pre-cleaning and pre-coating using nano technology. Your powder-coated parts will survive 200 hours of salt-spray testing.